- 技术文章

识别液压软管接头时的消除过程

2020-07-30 09:27:46 来源:识别液压软管接头时的消除过程

Process of Elimination When Identifying Hydraulic Hose Fittings

Thursday, August 24, 2017 by Fluid Gas Handling Team

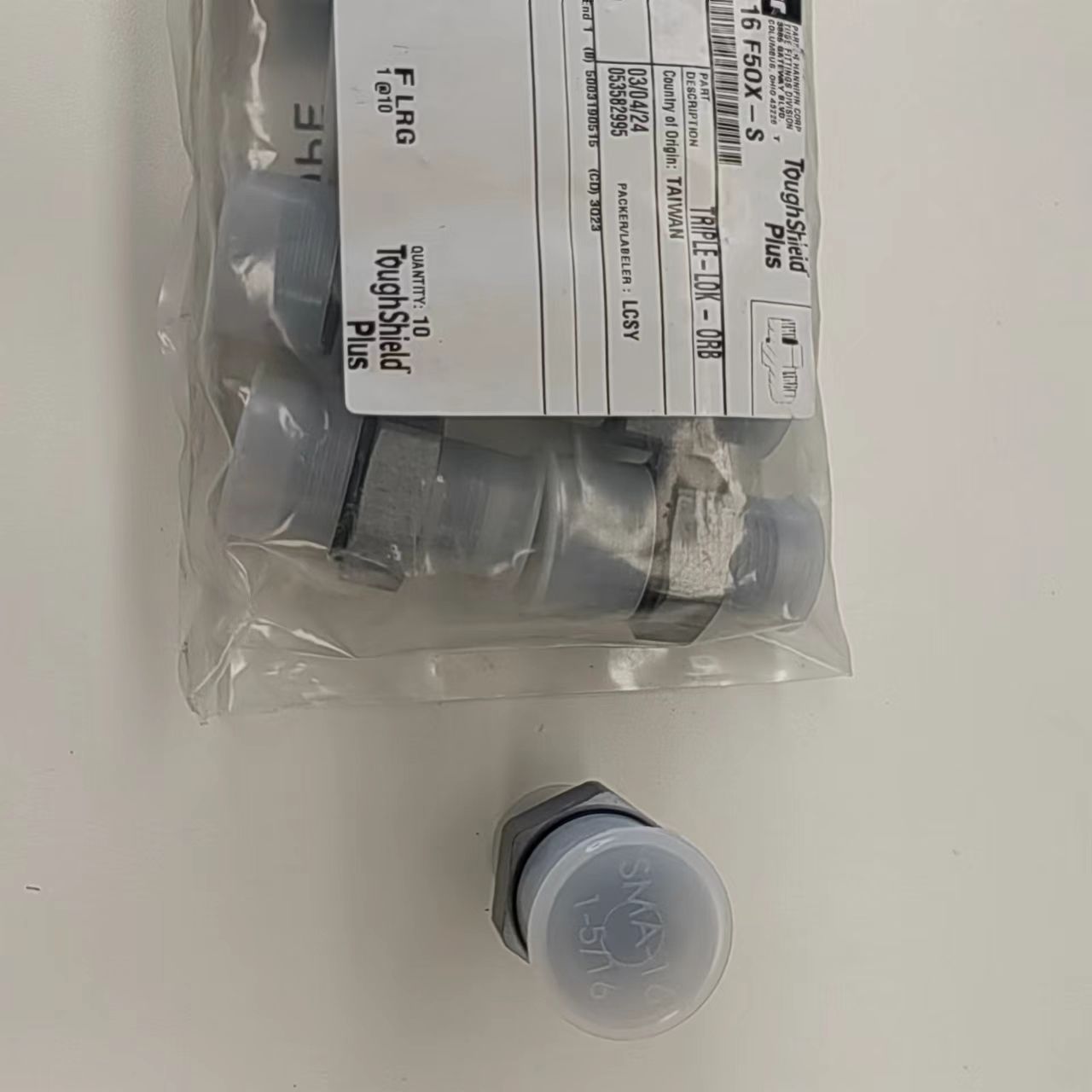

识别液压软管接头-软管和接头连接产品组-派克软管产品部工业机械和设备的设计和制造遍及世界的每个角落。仅液压系统便使用了无数不同类型的配件和适配器,它们具有不同的密封方法和螺纹形式。虽然通常可以通过外观来区分密封方法,但是螺纹形式看起来都一样,因此在需要对设备进行修改或维修时,很难识别它们并费时。但是,通过在卸载配件后进行消除的过程可以轻松地识别配件。首先,确定配件的类型-它是永久的还是可重复使用的?

液压软管接头可以是两种类型之一-永久或可重复使用。永久性或压接式液压接头广泛用于流体动力行业,因为它们比可重复使用的接头更容易,更快速地安装。压接接头也更可靠。要连接压接配件,您将需要压接或锻压设备。这些配件在组装时被挤压到软管上,当软管组件发生故障时将其丢弃。

由于可重复使用或可现场连接的液压软管接头被认为是“过时的技术”,因此今天并不常用。可重复使用的接头很容易识别,因为仅使用扳手和虎钳就可以将接头正确地安装在软管上。可重复使用的配件通常比卷边配件贵,并且在组装过程中更耗时。

识别接头和端口连接

必须正确识别液压系统中的端口和连接器,然后才能组装和安装正确的软管或管子组件。

Port Connections Tube/Hose Connections NPT/NPTF

BSPT (JIS-PT)

Metric Taper

SAE Straight Thread

ISO 6149

JIS-B2351

DIN Metric

BSPP (JIS-PF)

4-Bolt Flange37 Flare

30 Flare (Metric)

45 Flare

24 Flareless (SAE)

24 Flareless (DIN)

30 Flare (BSPP)

O-Ring Face Seal (ORFS)

60 NPSM Swivel

60 Cone (BSPP)

60 Cone (Metric)接下来,确定密封方法

液压接头的类型取决于其尺寸,配置和螺纹类型。软管接头的三种*常见类型是O形圈,对接角钢和螺纹。但是,还有其他几种类型的液压软管接头可用。

识别液压软管接头-派克软管产品部-O型圈密封件

O形圈:三种O形圈密封设计是O形圈凸台,平面O形圈密封和O形圈法兰。对于这些类型的联轴器,有一个O形圈密封件是创建密封件的主要组件。

配合角度:配合角度的一个示例是SAE 45°或JIC 37°,但也有其他角度。带有角座的配件具有用于密封的直螺纹或平行螺纹。当将公对母螺纹连接在一起时,螺纹本身实际上并不形成密封。取而代之的是,它们机械地起作用以将两个配合的角座放在一起,*终形成密封。

锥形螺纹:这些类型的接头具有两种类型的螺纹:公螺纹或母螺纹。公接头的外部具有螺纹,母接头的内部具有螺纹。识别液压软管接头-派克软管产品部-锥形螺纹当将外螺纹和内螺纹配对时,锥形螺纹会变形,从而在联轴器上施加压力,*终形成紧密密封。锥形螺纹可能不精确,但切勿使用胶带确保密封。胶带经常会在液压和气动系统中被禁止使用,因为它容易撕碎和污染敏感区域。还已知其润滑性会引起过度扭转。

然后,看看装修设计

确定密封方法后,目视检查O形圈,鼻座,座角和接头端接的位置。您可以从视觉上看到O形圈的位置以及鼻托的类型。但是,您将需要使用座椅规来确定座椅角度。

带有O形圈的配对角座:O型圈位置 鼻座 座角 接头端接 内 倒 60(含) 英国标准管道平行 内 倒 24(含) DIN24锥

O型圈端面密封:

O型圈位置 鼻座 座角 接头端接 在法兰槽中 平面 不适用 SAE O型圈法兰(代码61或62) 外 平面 不适用 SAE O型圈老板 在鼻子座位 平面 不适用 O型圈面密封

机械接头或配合角度:

O型圈位置 鼻座 座角 接头端接 没有 标准 37 JIC37喇叭 没有 标准 45 JIC / SAE45喇叭 没有 标准 30 日本工业标准和小松 没有 倒 不适用 公制立管 没有 倒 30 国家直管 没有 倒 45 SAE倒喇叭口 没有 倒 24 包容性 法式天然气24锥 没有,除了-20 标准 24 包容性 法式天然气24高压法兰

线程接口:

O型圈位置 鼻座 座角 接头端接 不适用 不适用 不适用 国家管道锥形 不适用 不适用 不适用 英制标准锥形管 *后,测量螺纹

用卡尺测量*大点的螺纹直径(外螺纹的外径(OD);内螺纹的内径(ID))。使用螺纹规确定每英寸的螺纹数。在浅色背景下比较规格和连接螺纹可确保读数准确。

派克的软管产品部具有阴影图像,可轻松确定线,锥和六角尺寸。单击这些图像以打印出有用的指南,以帮助识别液压接头。

确定需要更换的液压软管接头后,派克汉尼fin便成为理想的选择供应商。派克提供比其他任何制造商更多的液压软管选择,以及更多的液压接头尺寸。派克的软管产品部提供3/16“至3”的钢,黄铜和不锈钢配件。样式包括O形圈端面密封,喇叭口,公管,公制设计等等。定制的软管和软管接头也有各种配置,包括NPTF,JIC,SAE,GAZ,ISO,DIN,JIS和BSP。许多制造商还提供适合的挂图,以帮助进行识别过程。

Next, identify the sealing method

Identifying Hydraulic Hose Fittings - Product group of hose and fitting connections - Parker Hose Products DivisionIndustrial machines and equipment are designed and manufactured in every corner of the world. The hydraulic systems alone use countless different types of fittings and adapters with different sealing methods and thread forms. While the sealing method can often be distinguished by appearance, thread forms all seem to look the same, making it difficult and time-consuming to identify them when equipment modifications or repairs are needed. Identifying a fitting can be easily done, however, through the process of elimination after uninstalling the fitting.

First, determine the type of fitting – is it permanent or reusable?

Hydraulic hose fittings can be one of two types – permanent or reusable. Permanent or crimped hydraulic fittings are widely used in the fluid power industry because they are easier and quicker to attach than reusable fittings. Crimped fittings are also more reliable. To attach a crimped fitting, you will need crimping or swaging equipment. These fittings are squeezed onto the hose at assembly and are discarded when the hose assembly fails.

Reusable or field attachable hydraulic hose fittings are not commonly used today since they are considered "old technology."A reusable fitting is easily identifiable because it fits right onto a hose by using only a wrench and a vise. Reusable fittings typically cost more than crimped fittings and are more time consuming during the assembly process.

Identify fitting ends and port connections

Accurate identification of ports and connectors in a hydraulic system is necessary before the correct hose or tube assembly can be assembled and installed.

Port Connections Tube/Hose Connections

NPT/NPTF

BSPT (JIS-PT)

Metric Taper

SAE Straight Thread

ISO 6149

JIS-B2351

DIN Metric

BSPP (JIS-PF)

4-Bolt Flange

37 Flare

30 Flare (Metric)

45 Flare

24 Flareless (SAE)

24 Flareless (DIN)

30 Flare (BSPP)

O-Ring Face Seal (ORFS)

60 NPSM Swivel

60 Cone (BSPP)

60 Cone (Metric)

Next, identify the sealing method

Types of hydraulic fittings vary depending on their sizes, configuration, and thread types. The three most common types of hose fittings are O-ring, mated angle and threaded. However, there are several more types of hydraulic hose fittings available.

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - O-Ring SealsO-Ring: The three types of O-ring seal designs are O-ring boss, flat face O-ring seal and O-ring flange. With these types of couplings, there is an O-ring seal that is the main component in creating the seal.

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Mated Angle SealsMated Angle: An example of a mated angle is SAE 45° or JIC 37° but there are others as well. Fittings with an angle seat have straight or parallel threads for sealing. When the male and female counterparts are threaded together, the threads themselves do not actually form the seal. Instead, they function mechanically to bring the two mating angle seats together which ultimately forms the seal.

Tapered Threads: These types of fittings have two types of threads: male or female. Male fittings feature their threads on the outside and female fittings have threads on the inside. Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Tapered ThreadsWhen the male and female counterparts are threaded together, the tapered threads deform which applies pressure on the couplings ultimately making a tight seal. Tapered threads can be imprecise but never use tape to ensure the seal. Tape is often banned in hydraulic and pneumatic systems because of its tendency to shred and contaminate sensitive areas. Its lubricity has also been known to induce over-torquing.

Then, look at the fitting design

After you have determined the sealing method, visually look at the location of the O-ring, nose seat, seat angle and fitting termination. You can visually see the O-ring location as well as the type of nose seat. However, you will need to use a seat gauge to determine seat angle.

Mated Angle Seat with O-ring:

O-Ring Location Nose Seat Seat Angle Fitting Termination

Inside Inverted 60 Inclusive British Standard Pipe Parallel

Inside Inverted 24 Inclusive DIN 24 Cone

O-Ring Face Seal:

O-Ring Location Nose Seat Seat Angle Fitting Termination

In Flange Groove Flat Face N/A SAE O-Ring Flange (Code 61 or 62)

Outside Flat Face N/A SAE O-Ring Boss

At Nose Seat Flat Face N/A O-Ring Face Seal

Mechanical Joint or Mated Angle:

O-Ring Location Nose Seat Seat Angle Fitting Termination

None Standard 37 JIC 37 Flare

None Standard 45 JIC / SAE 45 Flare

None Standard 30 Japanese Industrial Standard & Komatsu

None Inverted N/A Metric Stand Pipe

None Inverted 30 National Pipe Straight

None Inverted 45 SAE Inverted Flare

None Inverted 24 Inclusive French Gaz 24 Cone

None, except -20 Standard 24 Inclusive French Gaz 24 High-Pressure Flange

Thread Interface:

O-Ring Location Nose Seat Seat Angle Fitting Termination

N/A N/A N/A National Pipe Tapered

N/A N/A N/A British Standard Pipe Tapered

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Visual Fitting Index

Lastly, measure the thread

With the caliper, measure the thread diameter of the largest point (Outside Diameter (O.D.) of male threads; Inside Diameter (I.D.) of female threads). Using the thread gauge, determine the number of threads per inch. Comparison of gauge and coupling threads against a lighted background will ensure an accurate reading.

Parker’s Hose Products Division has shadow images to easily determine thread, cone and hex size. Click on these images to print out a useful guide to assist in identifying hydraulic fittings.

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Male Pipe Thread Sizes Identifying Hydraulic Hose Fittings - Parker Hose Products Division - SAE Nut and Nipple Chart

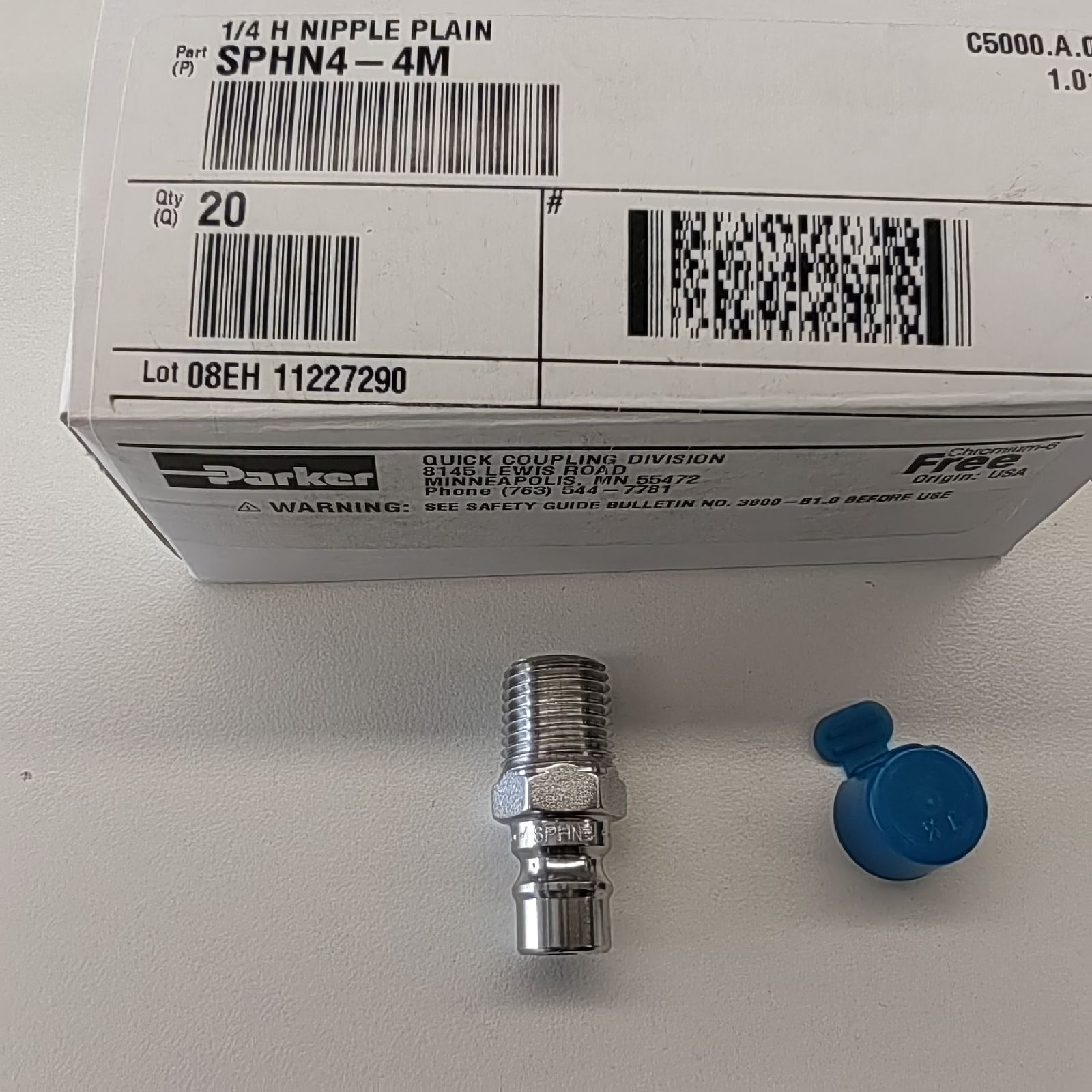

After you have determined the hydraulic hose fitting you need to replace, Parker Hannifin is an ideal supplier of choice. Parker offers the largest selection of hydraulic hoses plus more hydraulic fitting sizes than any other manufacturer. Parker’s Hose Products Division offers steel, brass, and stainless steel fittings from 3/16" to 3". Styles include O-ring face seal, flare, male pipe, metric designs and much more. Custom tube and hose fittings are also available in various configurations including NPTF, JIC, SAE, GAZ, ISO, DIN, JIS and BSP. Many manufacturers offer fitting wall charts as well to assist in the identification process.

Kyri McDonough, Hose Products Division, Parker HannifinArticle contributed by Kyri McDonough, marketing services manager at Hose Products Division, Parker Hannifin.

Other related topics on hydraulic hose, hose application, and selection criteria:

An Effective Way to Identify Hydraulic Fitting Orientation

Decoding a Hydraulic Hose Layline

Five Most Important Factors You Need to Consider for Hydraulic Fittings

Hydraulic Hose 101: Fast Facts

Successful Hydraulic Hose Assembly Starts Here

Going to Extremes: A Closer Look at Hydraulic Hoses

Categories

Fittings

Fluid and Gas Handling

Hose

Support

Previous PostNext Post

Have a question about Parker products or services? We can help: Contact Us!

Comments for Process of Elimination When Identifying Hydraulic Hose Fittings

Kevin Krizan

Hello, I have been trying to identify the correct part number for two fittings. I have parker # 13943-8-8 and 10643-8-8 a 90deg elbow and straight 43 series fittings which are made from steel. I need to replace them both with the same style but made from stainless steel. Can you please provide the correct part number to order for each? Also would the hose material be the same for stainless steel, if not please also provide part number for the correct hose.

Thank you in advance for the help.

Kyri McDonough

Stainless steel fittings have the exact same part number except that it ends in a C. For instance, 10643-8-8C would be the stainless part number.

Sushma Shetty

Nice and very informative blog, will also like to add that there is also a product known as hose clamp which also provides additional holding power and grip.

Thank you!

Please note that, in an effort to combat spam, comments with hyperlinks will not be published.

Leave a comment

Name

Email*

Your comment - (No HTML No Links)

Type the text from the image below

Captcha

Subscribe to This Team

RSS Email

To subscribe to the RSS Feed, add its URL to an RSS Reader of your choice.

Manage Email Subscriptions

About The Authors

Contact Fluid Gas Handling Team

Email

More posts by Fluid Gas Handling Team

Fluid Gas Handling Team's Bio

Categories

Aerospace

Climate Control

Electromechanical

Filtration

Fluid & Gas Handling

Hydraulics

Pneumatics

Process Controls

Sealing & Shielding

View All

Parker Support

Support

Tweets by Parker

Connect With Us

About Parker Contact Parker Careers Working With Parker Investors News ParkerStore Brands

Engineering your succes Parker Hannifin Corp 2020

Site Map Safety Privacy Policies Terms and Conditions

Blog Home Contact Parker

Products

Division

Literature

Distributors

About Parker

Fluid Gas Handling

Search

Process of Elimination When Identifying Hydraulic Hose Fittings

Thursday, August 24, 2017 by Fluid Gas Handling Team

Print Friendly and PDF

Identifying Hydraulic Hose Fittings - Product group of hose and fitting connections - Parker Hose Products DivisionIndustrial machines and equipment are designed and manufactured in every corner of the world. The hydraulic systems alone use countless different types of fittings and adapters with different sealing methods and thread forms. While the sealing method can often be distinguished by appearance, thread forms all seem to look the same, making it difficult and time-consuming to identify them when equipment modifications or repairs are needed. Identifying a fitting can be easily done, however, through the process of elimination after uninstalling the fitting.

First, determine the type of fitting – is it permanent or reusable?

Hydraulic hose fittings can be one of two types – permanent or reusable. Permanent or crimped hydraulic fittings are widely used in the fluid power industry because they are easier and quicker to attach than reusable fittings. Crimped fittings are also more reliable. To attach a crimped fitting, you will need crimping or swaging equipment. These fittings are squeezed onto the hose at assembly and are discarded when the hose assembly fails.

Reusable or field attachable hydraulic hose fittings are not commonly used today since they are considered "old technology."A reusable fitting is easily identifiable because it fits right onto a hose by using only a wrench and a vise. Reusable fittings typically cost more than crimped fittings and are more time consuming during the assembly process.

Identify fitting ends and port connections

Accurate identification of ports and connectors in a hydraulic system is necessary before the correct hose or tube assembly can be assembled and installed.

Port Connections Tube/Hose Connections

NPT/NPTF

BSPT (JIS-PT)

Metric Taper

SAE Straight Thread

ISO 6149

JIS-B2351

DIN Metric

BSPP (JIS-PF)

4-Bolt Flange

37 Flare

30 Flare (Metric)

45 Flare

24 Flareless (SAE)

24 Flareless (DIN)

30 Flare (BSPP)

O-Ring Face Seal (ORFS)

60 NPSM Swivel

60 Cone (BSPP)

60 Cone (Metric)

Next, identify the sealing method

Types of hydraulic fittings vary depending on their sizes, configuration, and thread types. The three most common types of hose fittings are O-ring, mated angle and threaded. However, there are several more types of hydraulic hose fittings available.

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - O-Ring SealsO-Ring: The three types of O-ring seal designs are O-ring boss, flat face O-ring seal and O-ring flange. With these types of couplings, there is an O-ring seal that is the main component in creating the seal.

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Mated Angle SealsMated Angle: An example of a mated angle is SAE 45° or JIC 37° but there are others as well. Fittings with an angle seat have straight or parallel threads for sealing. When the male and female counterparts are threaded together, the threads themselves do not actually form the seal. Instead, they function mechanically to bring the two mating angle seats together which ultimately forms the seal.

Tapered Threads: These types of fittings have two types of threads: male or female. Male fittings feature their threads on the outside and female fittings have threads on the inside. Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Tapered ThreadsWhen the male and female counterparts are threaded together, the tapered threads deform which applies pressure on the couplings ultimately making a tight seal. Tapered threads can be imprecise but never use tape to ensure the seal. Tape is often banned in hydraulic and pneumatic systems because of its tendency to shred and contaminate sensitive areas. Its lubricity has also been known to induce over-torquing.

Then, look at the fitting design

After you have determined the sealing method, visually look at the location of the O-ring, nose seat, seat angle and fitting termination. You can visually see the O-ring location as well as the type of nose seat. However, you will need to use a seat gauge to determine seat angle.

Mated Angle Seat with O-ring:

O-Ring Location Nose Seat Seat Angle Fitting Termination

Inside Inverted 60 Inclusive British Standard Pipe Parallel

Inside Inverted 24 Inclusive DIN 24 Cone

O-Ring Face Seal:

O-Ring Location Nose Seat Seat Angle Fitting Termination

In Flange Groove Flat Face N/A SAE O-Ring Flange (Code 61 or 62)

Outside Flat Face N/A SAE O-Ring Boss

At Nose Seat Flat Face N/A O-Ring Face Seal

Mechanical Joint or Mated Angle:

O-Ring Location Nose Seat Seat Angle Fitting Termination

None Standard 37 JIC 37 Flare

None Standard 45 JIC / SAE 45 Flare

None Standard 30 Japanese Industrial Standard & Komatsu

None Inverted N/A Metric Stand Pipe

None Inverted 30 National Pipe Straight

None Inverted 45 SAE Inverted Flare

None Inverted 24 Inclusive French Gaz 24 Cone

None, except -20 Standard 24 Inclusive French Gaz 24 High-Pressure Flange

Thread Interface:

O-Ring Location Nose Seat Seat Angle Fitting Termination

N/A N/A N/A National Pipe Tapered

N/A N/A N/A British Standard Pipe Tapered

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Visual Fitting Index

Lastly, measure the thread

With the caliper, measure the thread diameter of the largest point (Outside Diameter (O.D.) of male threads; Inside Diameter (I.D.) of female threads). Using the thread gauge, determine the number of threads per inch. Comparison of gauge and coupling threads against a lighted background will ensure an accurate reading.

Parker’s Hose Products Division has shadow images to easily determine thread, cone and hex size. Click on these images to print out a useful guide to assist in identifying hydraulic fittings.

Identifying Hydraulic Hose Fittings - Parker Hose Products Division - Male Pipe Thread Sizes Identifying Hydraulic Hose Fittings - Parker Hose Products Division - SAE Nut and Nipple Chart

After you have determined the hydraulic hose fitting you need to replace, Parker Hannifin is an ideal supplier of choice. Parker offers the largest selection of hydraulic hoses plus more hydraulic fitting sizes than any other manufacturer. Parker’s Hose Products Division offers steel, brass, and stainless steel fittings from 3/16" to 3". Styles include O-ring face seal, flare, male pipe, metric designs and much more. Custom tube and hose fittings are also available in various configurations including NPTF, JIC, SAE, GAZ, ISO, DIN, JIS and BSP. Many manufacturers offer fitting wall charts as well to assist in the identification process.

Kyri McDonough, Hose Products Division, Parker HannifinArticle contributed by Kyri McDonough, marketing services manager at Hose Products Division, Parker Hannifin.

新发布

-

信德迈科技(北京)有限公司期待您的来电!

信德迈科技(北京)有限公司期待您的来电!13910122694

内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。信德迈科技(北京)有限公司 电话:010-84282935 手机:13910122694 地址: 北京朝阳区望京街10号望京SOHO-T1-C座2115室

扫一扫,手机浏览

扫一扫,手机浏览